*REQUIRES MILLING (LEVEL-1) & TURNING (LEVEL-1) AT MINIMUM…

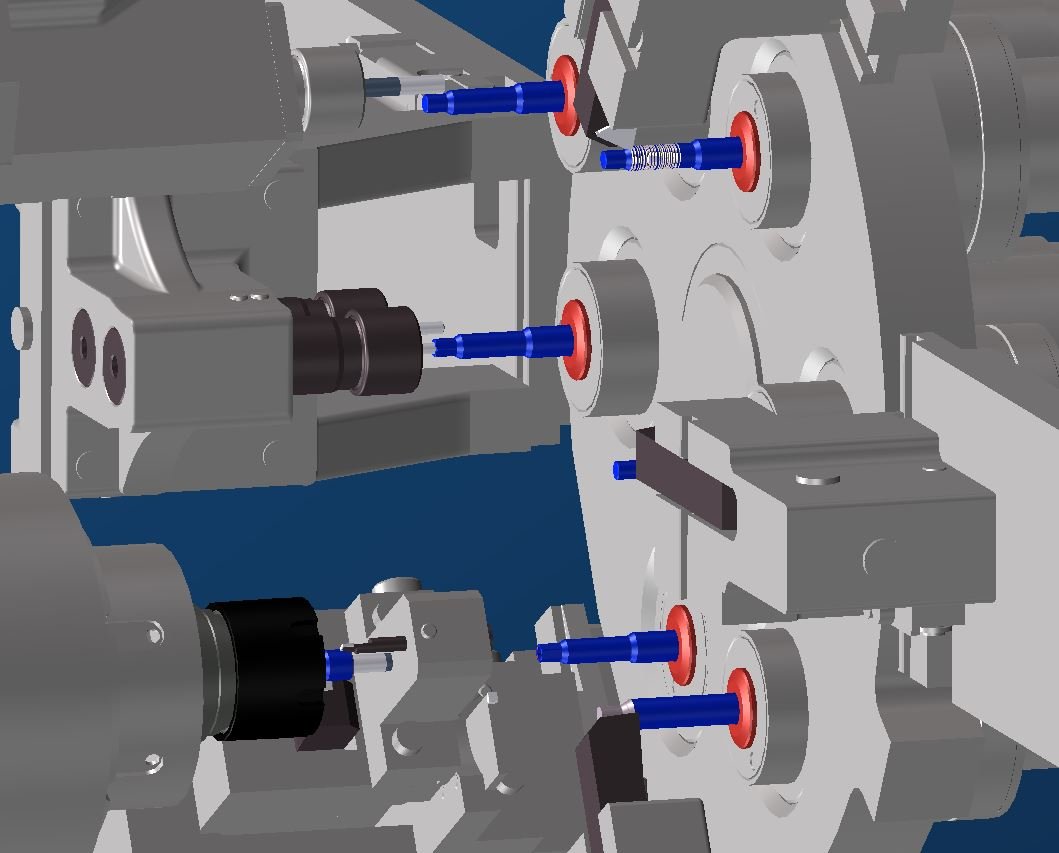

Swiss-style Machine Tool Programming

Swiss-style machine tools are becoming extremely popular, especially for ultra-high precision parts and complete lights out machining. GibbsCAM supports Swiss-style CNC and provides an easy-to-use tool for programming these complex machines. Utilizing an intuitive sync manager in addition to UKM technology, GibbsCAM is the powerful and easy-to-use solution for programming Swiss-style machinery.

Sync Manager

Sync Manager provides an easy to understand, intuitive, graphical interface allowing you to focus on optimizing your process. The Sync Manager handles all the underlying complexities for you.

Displays multiple, parallel process flows

Calculate operation times to optimize machine moves

Control non-cutting machine moves

Automatically check for invalid operations orsynchronization

Utility Operation Support

Supports the entire range of utility operations used by your machine tool, providing full control all the way to posted output. Fully controlling non-cutting moves ensures that you fully utilize your MTM machine tool to maximize your return on investment.

Sub-spindle programming

Bar feeders and part catchers

Full off-part turret control and placement

Integrated Process Rendering

Integrated simulation allows you to fully verify your programs including multiple tools cutting at the same time, on-screen, reducing the risk of gouges and collisions.

Visual gouge checking

Check efficiency of cutting and non-cutting moves

Simultaneously visualize multiple workflows

Machine-Specific Setup

Swiss machine tools represent some of the most complex machine tool configurations available today. With GibbsCAM, your machine tool’s specific configuration is captured by factory-supplied settings so that you are accurately programming all its capabilities. This way you can be sure that you are taking full advantage of your Program machines with any number of turrets and spindles machine tool for maximum productivity.